News & Press

- Home

- >>

- Info

- >>

- News & Press

- >>

- View Details

Got any Questions?

CALL US NOW

Mobile: 0086 186 5335 4363

Tel / Fax: 0086 533 3588750

Email: info@crusher-world.com

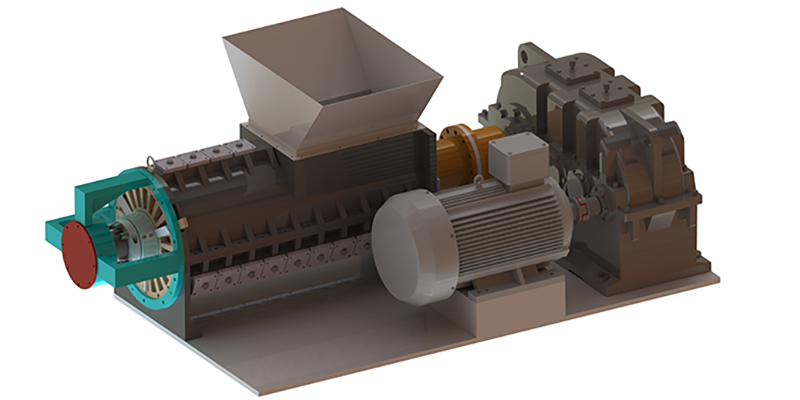

Innovation Driven: Spiral Crusher Leads a New Era of High-Efficiency Crushing

With its low speed and high torque, highly wear-resistant blades, and energy-saving design, the spiral crusher has become a new choice for high-efficiency crushing in the rubber and plastics industry.

In today’s fast-growing recycling industry, the Spiral Crusher stands out as a cutting-edge solution for efficient, energy-saving, and environmentally friendly crushing.

Utilizing a low-speed, high-torque design, it combines shearing and spiral compression to achieve high crushing efficiency while minimizing heat buildup and energy consumption. This ensures that elastic materials such as rubber and EVA retain their quality throughout processing.

With wear-resistant alloy blades and a modular design, the Spiral Crusher is easy to maintain, offering longer service life and reduced operating costs. It operates with low noise and vibration, aligning perfectly with sustainable industrial practices.

Adaptable to materials like waste tires, rubber scraps, PE foam, EVA, and more, it’s an ideal solution for recycling enterprises aiming for high productivity and consistent quality.

Utilizing a low-speed, high-torque design, it combines shearing and spiral compression to achieve high crushing efficiency while minimizing heat buildup and energy consumption. This ensures that elastic materials such as rubber and EVA retain their quality throughout processing.

With wear-resistant alloy blades and a modular design, the Spiral Crusher is easy to maintain, offering longer service life and reduced operating costs. It operates with low noise and vibration, aligning perfectly with sustainable industrial practices.

Adaptable to materials like waste tires, rubber scraps, PE foam, EVA, and more, it’s an ideal solution for recycling enterprises aiming for high productivity and consistent quality.