News & Press

- Home

- >>

- Info

- >>

- News & Press

- >>

- View Details

Got any Questions?

CALL US NOW

Mobile: 0086 186 5335 4363

Tel / Fax: 0086 533 3588750

Email: info@crusher-world.com

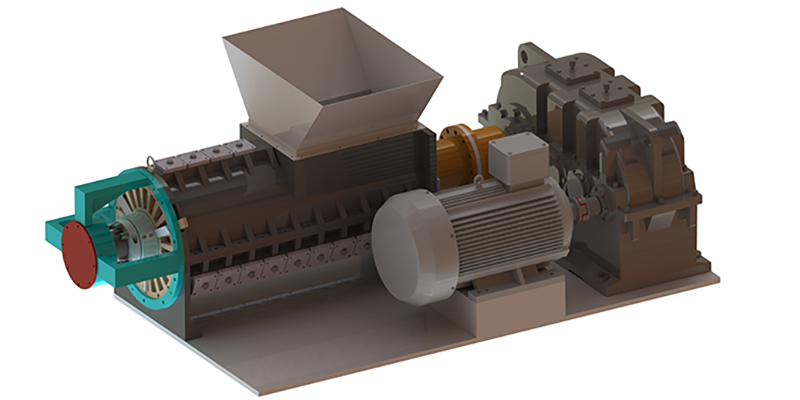

Dual-Shaft Shredder Revolutionizes Waste Recycling

In a significant leap forward for waste management technology, the latest dual-shaft shredder has emerged as a powerhouse solution for industries grappling with tough recycling challenges. Combining raw power, precision, and eco-friendly innovation, this machine is setting new benchmarks in efficiency and sustainability.

Breaking Down the Innovation

Engineered for high-volume industrial applications, the dual-shaft shredder utilizes two synchronized, counter-rotating shafts fitted with ultra-durable alloy steel blades. Unlike traditional single-shaft models, this design delivers double the shear force, enabling it to effortlessly process:

Metals (scrap cars, aluminum, wires)

Plastics (rigid PVC, HDPE pipes, PET bottles)

Tires & Rubber (passenger tires, industrial conveyor belts)

E-Waste (circuit boards, appliances)

Municipal Solid Waste (MSW) (furniture, packaging, mixed debris)

Why Industries Are Switching

Unmatched Efficiency

Throughput rates of 1–20 tons/hour, reducing processing time by 30% compared to single-shaft alternatives.

Adjustable output sizes (50–300mm) via modular screens, catering to diverse recycling needs.

Built to Last

Hydraulic or gear-driven motors provide relentless torque without overheating.

Blades made of heat-treated CrMoV steel withstand extreme abrasion, slashing maintenance costs.

Smart & Safe Operation

PLC automation monitors performance in real-time, with auto-reverse functions to prevent jams.

Noise levels below 75dB and optional dust collectors align with global EPA and OSHA standards.

Sustainability Boost

Pre-shredding waste for Waste-to-Energy (WtE) plants improves combustion efficiency.

Enables closed-loop recycling by transforming scrap into reusable raw materials.

Industry Impact

"With landfills overflowing and recycling targets tightening, dual-shaft shredders are no longer optional—they’re essential," says [Industry Expert Name], CEO of [Recycling Firm]. "Our clients have cut disposal costs by 40% while meeting zero-waste mandates."

Global Adoption & Availability

Already deployed in Europe, North America, and Asia, these shredders are customizable for small recyclers to large waste management plants. Manufacturers now offer leasing programs and AI-driven predictive maintenance to ease adoption.

The Future of Shredding?

As circular economy goals gain urgency, dual-shaft technology is poised to dominate. Next-gen models with IoT connectivity and energy-recovery systems are already in development.