News & Press

- Home

- >>

- Info

- >>

- News & Press

- >>

- View Details

Got any Questions?

CALL US NOW

Mobile: 0086 186 5335 4363

Tel / Fax: 0086 533 3588750

Email: info@crusher-world.com

The Critical Role of Grinding in Wastewater Treatment Pump Protection

·Introduction

As the world's population continues to grow, so does the need for effective wastewater treatment. Properly managing wastewater is essential to maintaining the health and safety of our communities and the environment. A critical component of wastewater treatment is the protection of the pumps used in these systems. In this blog post, we'll explore the importance of grinding in wastewater treatment pump protection and why it's crucial to the overall efficiency and success of these systems.

·The Role of Pumps in Wastewater Treatment

Wastewater treatment plants rely on a variety of pumps to move water and waste through the treatment process. These pumps are responsible for tasks such as transferring raw sewage, pumping treated effluent, and recirculating sludge. The pumps must be able to handle solid materials, including debris and waste, which can be found in wastewater.

·The Challenge: Protecting Pumps from Damage

One of the most significant challenges faced in wastewater treatment is the potential damage to pumps caused by solid materials, such as rags, plastics, and other debris. If these materials are not adequately managed, they can clog or damage the pumps, leading to costly repairs, downtime, and decreased efficiency in the treatment process.

·The Solution: Grinding in Wastewater Treatment

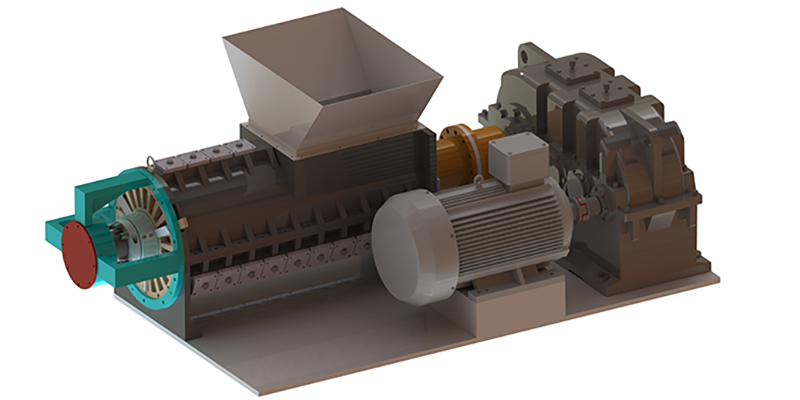

Grinding plays a critical role in protecting wastewater treatment pumps from damage. By breaking down solid materials into smaller particles, grinding equipment helps prevent clogs and damage to pumps, ensuring they continue to operate efficiently.

For example, the waste water grinding grille made by Zibo United Tech Machinery Co., Ltd. can be directly installed in the waste water flow path. These grilles use sharp hardened steel cutters to cut and reduce the size of the chips, making it easier for the pump to handle and transport the material.

·Benefits of Grinding for Wastewater Pump Protection

1. Increased Pump Efficiency: With solid materials effectively ground into smaller particles, pumps can operate more efficiently and with less strain. This reduces the likelihood of clogs and damage, ensuring the wastewater treatment process runs smoothly.

2. Reduced Maintenance Costs: Grinding helps prevent clogs and pump damage, which in turn leads to less frequent maintenance and repair costs. This not only saves time but also reduces the overall expense of wastewater treatment plant operation.

3. Prolonged Pump Lifespan: By protecting pumps from damage and reducing strain, grinding equipment helps extend the life of wastewater treatment pumps. This results in long-term cost savings and increased operational efficiency.

4. Environmental Impact: Properly functioning pumps are essential for effective wastewater treatment. Grinding equipment ensures that pumps can effectively manage solid materials, leading to more successful treatment outcomes and a reduced impact on the environment.

Welcome to contact us for more detailed product information. We can recommend the selection of appropriate models, integrated to meet the production needs of the program. Allow customers to control the investment as far as possible, access to high cost-effective equipment products or production lines.

As the world's population continues to grow, so does the need for effective wastewater treatment. Properly managing wastewater is essential to maintaining the health and safety of our communities and the environment. A critical component of wastewater treatment is the protection of the pumps used in these systems. In this blog post, we'll explore the importance of grinding in wastewater treatment pump protection and why it's crucial to the overall efficiency and success of these systems.

·The Role of Pumps in Wastewater Treatment

Wastewater treatment plants rely on a variety of pumps to move water and waste through the treatment process. These pumps are responsible for tasks such as transferring raw sewage, pumping treated effluent, and recirculating sludge. The pumps must be able to handle solid materials, including debris and waste, which can be found in wastewater.

·The Challenge: Protecting Pumps from Damage

One of the most significant challenges faced in wastewater treatment is the potential damage to pumps caused by solid materials, such as rags, plastics, and other debris. If these materials are not adequately managed, they can clog or damage the pumps, leading to costly repairs, downtime, and decreased efficiency in the treatment process.

·The Solution: Grinding in Wastewater Treatment

Grinding plays a critical role in protecting wastewater treatment pumps from damage. By breaking down solid materials into smaller particles, grinding equipment helps prevent clogs and damage to pumps, ensuring they continue to operate efficiently.

For example, the waste water grinding grille made by Zibo United Tech Machinery Co., Ltd. can be directly installed in the waste water flow path. These grilles use sharp hardened steel cutters to cut and reduce the size of the chips, making it easier for the pump to handle and transport the material.

·Benefits of Grinding for Wastewater Pump Protection

1. Increased Pump Efficiency: With solid materials effectively ground into smaller particles, pumps can operate more efficiently and with less strain. This reduces the likelihood of clogs and damage, ensuring the wastewater treatment process runs smoothly.

2. Reduced Maintenance Costs: Grinding helps prevent clogs and pump damage, which in turn leads to less frequent maintenance and repair costs. This not only saves time but also reduces the overall expense of wastewater treatment plant operation.

3. Prolonged Pump Lifespan: By protecting pumps from damage and reducing strain, grinding equipment helps extend the life of wastewater treatment pumps. This results in long-term cost savings and increased operational efficiency.

4. Environmental Impact: Properly functioning pumps are essential for effective wastewater treatment. Grinding equipment ensures that pumps can effectively manage solid materials, leading to more successful treatment outcomes and a reduced impact on the environment.

Welcome to contact us for more detailed product information. We can recommend the selection of appropriate models, integrated to meet the production needs of the program. Allow customers to control the investment as far as possible, access to high cost-effective equipment products or production lines.