News & Press

- Home

- >>

- Info

- >>

- News & Press

- >>

- View Details

Got any Questions?

CALL US NOW

Mobile: 0086 186 5335 4363

Tel / Fax: 0086 533 3588750

Email: info@crusher-world.com

Shred the Ragger Wire from Carton Pulp Factory

Posted 12-18,2020

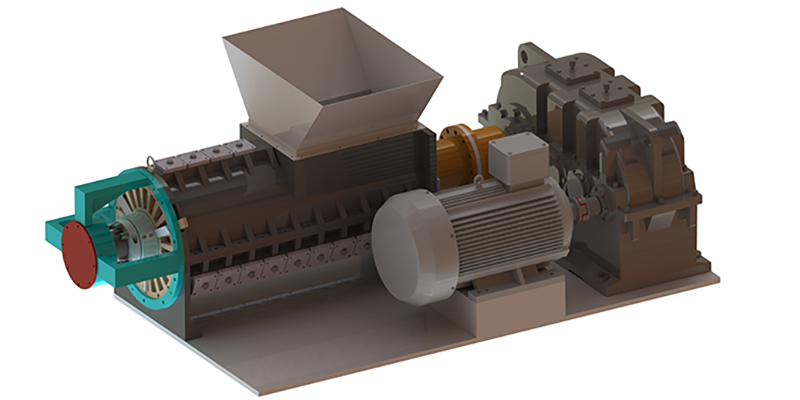

The rope garbage crusher enters into the shredding box body through the material feeding system. The shredding blade is loaded on the box body. After the shredding blade ripping, squeezing, shearing and other comprehensive functions, the shredding material into small pieces is discharged from the lower part of the box body.

The metal, plastic and pulp can be separated through the crushing and recycling system of the rope breaker. The metal can be reused through smelting, the plastic can be used for granulation, and the pulp can be made into recycled paper to achieve resource regeneration and protect the environment.

However, material through the rope crusher is a key process, the need to crush out even material to effectively separate, this needs the appropriate rope disposal plan, Zibo United Tech can according to your use and output, output particle size, provide a set of low cost, high output of paper mill rope crushing production line.

Biaxial shredding machine driven by biaxial independent, thus in the production, make the material produces corresponding crushed, to achieve automatic feeding function, the unique structure and the corners of rotary cutter knife shaft, in the process of production of low speed high torque, won't appear the phenomenon of winding shaft, or stuck equipment, so as to improve the production efficiency, the equipment is suitable for crushing all kinds of toughness and high viscosity material.

It has many advantages in production, environmental protection, recycling and so on.

The paper mill rope crusher is driven by planetary reducer, and the blade is made of imported alloy steel, which has strong wear resistance and strength.

Characteristics of the treatment system of United Tech rope garbage crusher: shear crushing, reducing labor intensity;

Self-discharging iron remover can realize automatic iron removal.

High strength and impact to metal materials can be broken as usual;

Bearing six - fold seal system, suitable for complex working conditions.

Previous:Zibo United Tech Machinery Co. LTD