Shredder

- Home

- >>

- Products

- >>

- Shredder

- >>

- View Details

Got any Questions?

CALL US NOW

Mobile: 0086 186 5335 4363

Tel / Fax: 0086 533 3588750

Email: info@crusher-world.com

Small Double Shaft Shredder

Double Shaft Shredder Introduction:

Double shaft shredder have been designed for a wide array of applications and industries, suitable for shredding solid material such as E-waste, metal, wood, plastic, scrap tires, packaging barrel. Pallets, etc. And particularly well suited to the size reduction of bulky or voluminous materials which could include contamination such as metals or stones. Depending on input material and the following process the shredded material can be used directly or go into the next setp of size reduction. It can efficient to increase the bulk density and decrease the transportation cost. It is widely used in industry waste recycling, medical recycling, electronic recycling, pallet recycling, municipal solid waste recycling, plastic recycling, tire recycling, paper making industry, etc.

D series double shaft shredder has two rotors built into the machine that rotate at low speeds, high torque and low noise. With the function of Siemens microcomputer control system, it is possible to control automatically start, stop. Automatic reverse sensors to protect the machine against over loading and jamming.

Welcome to contact with us to get more details product information. We are glad to introduce you the most suitable machine, design the most reasonable proposal as your production requirements. Our task is to support our customers who are in the solid waste & refuse management industries to get a higher production efficient, improve their product quality and value so that they can get a greatest progress in the keen competition.

Double Shaft Shredder Advantage :

* D series has two rotors built into the machine that rotate at low speeds, high torque and low noise. With the function of Siemens microcomputer control system, it is possible to control automatically start, stop. Automatic reverse sensors to protect the machine against over loading and jamming.

* Motor + the Rotor is drived by the reducer, get the effect of slow speed and high torque shredding.

* Six enclosed sealing bearing protection design, waterproof and dustproof, so the life of bearing can be prolonged.

* The wearing blade can be repaired by the most advanced cutting tool coating and welding technology. The blade can be repeated use, reduce the maintenance costs.

* Separated design to the shredding chamber, the frame can be easily discharged the whole Shaft (Rotor, Blade, Bearing, Sealed system).

* Blade is spiral arrangement, get effective shredding.

* Adopt the Hexagon to the blade inner hole and the main rotor, ensuring the blade stability and get equal force.

* To ensure durability and flexibility, we can offer the different kinds of Blades according to different materials.

Double Shaft Shredder Applications:

Metal material :Aluminum material, motor shell, oil drum, waste vehicle crust ,ferrous waste, waste steel plate, etc.

Waste tire: passenger car tire, truck tire, OTR tire, etc.

Plastics: plastic drum, packing case, plastic pallet, plastic can, etc.

Waste treatment:medical waste, hazardous waste ,industrial garbage, kitchen garbage, animal carcass, etc.

Electronic waste: waste fridge, TV set,Washing machine, etc.

Safe disposal: hard disk, expired food,paper, medicine, etc.

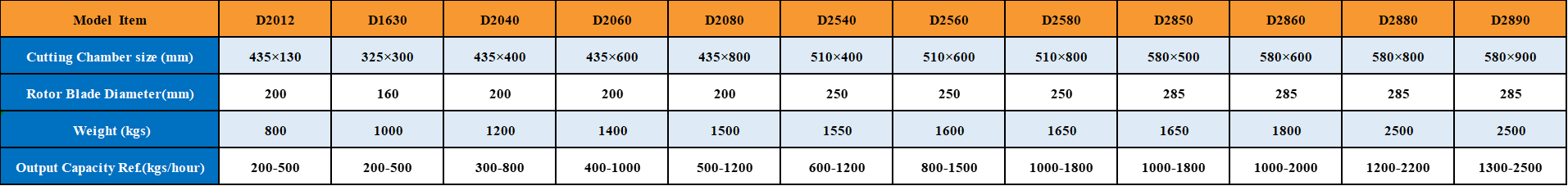

Double Shaft Shredder specification:

Note:

1. The voltage about the power supply can be selected by the customer’s specific requirements.

2. The shredder capacity can be influenced by the material composition and output size.

We provide Customized Machines. The above specifications are only for reference and subject to change without prior notice, please confirm with our sales representative when making order.

Previous:Single Shaft Shredder