Granulator

- Home

- >>

- Products

- >>

- Granulator

- >>

- View Details

Got any Questions?

CALL US NOW

Mobile: 0086 186 5335 4363

Tel / Fax: 0086 533 3588750

Email: info@crusher-world.com

Film Granulator

Descriptions

The GM Series -specify for Film and Bottle Granulator has a centrally hinged two-piece cutting chamber with a robust welded steel construction, with the upper and lower sections of the housing meeting horizontally. Reversible stator knives with double cutting edges are fitted as single elements to the lower section of the housing, allowing multiple re-sharpening and adjustment of the stator knives. There is a hinged screen cradle and hinged door for easy screen access.

The v-cut cutting geometry offers distinct advantages over other rotor designs, including higher throughput with reduced power consumption, better quality cut, and lower noise levels. Specially designed knife setting jig means that the knives can be adjusted from outside the machine, significantly reducing the downtime required to change/set knives.

The base frame has a solid welded construction with anti-vibration rubber feet to reduce vibration and noise. The drive motor is mounted on tension rails to allow easy adjustment of the V-belt tension. Integrated suction trough for material discharge. Specially designed hopper with 3 sets of curtains to prevent material flybacks. Integrated rundown safety device prevents access to the rotor until it has come to a complete stop. A safety switch prevents machine startup when the front panel is open and the machine features emergency stop buttons on the machine body and control panel.

Features

- Complete soundproofed enclosure

- Deflector wedge

- V-cut technology

- Heavy duty bearings

- Oversized external bearing housings

- Knives are externally adjustable

- Robust welded steel construction

- Wide choice of rotor variations

- Electrical hydraulic control - to open housing

- Electrical hydraulic control - to open screen cradle

- Replaceable wear plates

- Amp meter control

- Integrated control panel

- Soundproof conveyor channel

- Extra flywheel

- Double infeed hopper

- Roller feeder

- Mounted screw feeders in hopper Winding protection

- Metal detector

- Metal separator

- Bespoke colour scheme

- Increased motor drive

- PLASTICS

- RUBBER

- WOOD

- BIOMASS

- PAPER

- ALTERNATIVE FUELS (RDF/SRF)

- DOMESTIC & COMMERCIAL WASTE

Note:

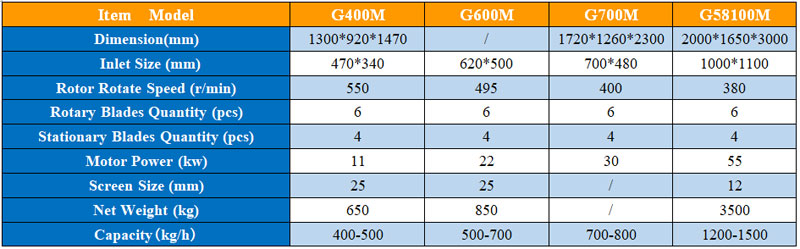

1. The voltage and motor power about the power supply can be selected by the customer’s specific requirements.

2. The granulator capacity can be influenced by the material composition and output size.

We provide customized granulator. The above specifications are only for reference and subject to change without prior notice, please confirm with our sales representative when making order.

Previous:Powerful Granulator