Crusher

- Home

- >>

- Products

- >>

- Crusher

- >>

- View Details

Got any Questions?

CALL US NOW

Mobile: 0086 186 5335 4363

Tel / Fax: 0086 533 3588750

Email: info@crusher-world.com

Double Roller Crusher

Double Roller Crusher Introduction:

Double Roller Crusher Introduction:

PG double roller crusher from United Tech Machinery is also called 2 Roller crusher. We have 2 kinds of twin roller crusher, one with the surface as teeth, another with the surface of the roller as smooth. utmach brand roller crusher are made of high manganese steel, which can stand up to heat treatment. Double roller crusher is suitable for such industries as cement, chemical industry, electric power, mine, building materials and metallurgy. Mainly used for secondary and fine crushing materials with soft or middle hardness like coal, coke, limestone, coal, coke, clinker, granite, basalt, cement, brick, tile, building material etc. Size of the input material is large, the particle size of the output product can be controlled, and it is possible to effectively destroy the material strength is less than 160 Mpa.

Double Roller Crusher Working Principle:

The materials are drawn into the gap between the rollers by their rotating motion and a friction angle formed between the rollers and the particle, called the nip angle. The two rollers force the particle between their rotating surface into the ever smaller gap area, and it fractures from the compressive forces presented by the rotating rollers.

Double Roller Crusher Advantages:

* Compact structure, reliable performance

* Low noise and high efficiency

* Easy to install and only need simple foundation

* It can adjust the pressure and size easily, and can be made to meet the customer's request

* Low attrition rate and easy to maintainance

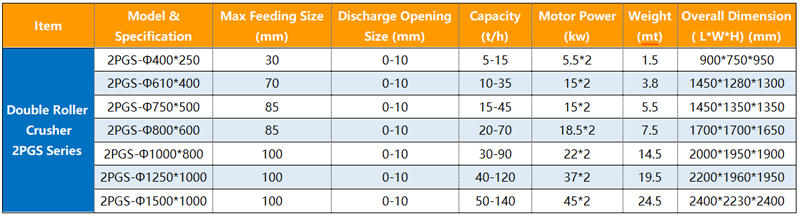

Double Roller Crusher Specification:

Note:

1. The voltage about the power supply can be selected by the customer’s specific requirements.

2. The crusher capacity can be influenced by the material composition and output size.

We provide customized machines. The above specifications are only for reference and subject to change without prior notice, please confirm with our sales representative when making order.