Chipper

- Home

- >>

- Products

- >>

- Chipper

- >>

- View Details

Got any Questions?

CALL US NOW

Mobile: 0086 186 5335 4363

Tel / Fax: 0086 533 3588750

Email: info@crusher-world.com

Mobilizable Chipper

Mobile Diesel Engine type wood chipper from United Tech is mainly used to crush big wood logs or timber wood branches, furniture waste, long bamboo into small chips. It widely used in the chipboard factory, medium/ high density fiberboard factory, straw factory, biological electric plant, wood chip factory, etc. The thickness of last chips is 3mm-5mm, length and width about 20-50mm, the knives gap can be adjusted, the outlet chips dimension will be adjusted.

Drum wood chipper contains main machine, blade rotor, feeding belt conveyor, hydraulic system, etc. the main machine body is welded with high strength steel plate. The hydraulic system is consisting of oil pump, hydro cylinder, which can start up the cover for blades changes and maintenance.

This series wood chipper machine adopts grab machine feeding, can call the template, straw, branches and other kinds of biological power plant fuel, the benefits of this device is to move around freely, broken branches broken big bad transportation convenience, and grasp the machine feeding (manual), can also according to require the use of remote control, or combined with automatic start-stop function, the feed is when the main motor load big, feed can be automatic start-stop, so that it can greatly save the human.

The wood chipper p machine adopts chain plate type intelligent feeding, which can automatically adjust the feeding speed according to the load of the main motor.

It makes the machine run at full load to avoid no-load operation, makes the feeding more smoothly, and greatly improves the production capacity. It is the ideal recommended equipment for biomass power plant.

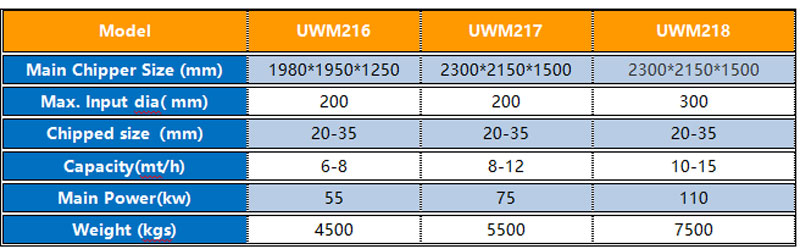

Wood Chipper specification:

Note:

1. The voltage and motor power about the power supply can be selected by the customer’s specific requirements.

2. The chipper capacity can be influenced by the material composition and output size.

We provide customized chipper. The above specifications are only for reference and subject to change without prior notice, please confirm with our sales representative when making order.

Previous:Wood Chipper MG1000

Next:Drum Biomass Chipper